I had an urge of inspiration lately and wanted to cook some ambitious meals. I recently had some good news about my career and wanted to celebrate so I thought a nice steak would be fitting.

The first meal I cooked was centered around a ribeye I got from a local butcher, Cooper Bros. This is a local butcher that was founded about a year ago in Lexington, KY. The ribeye I got was $23.99/lb which is pricey but it's locally sourced and is supposed to be really good. I talked to the butcher and he suggested that next time I should look into getting "chuck steak" which is similar to ribeye but a much cheaper cut.

I also had some Ricotta and Parmesean which I got to make some gnudi but it turned into a huge mushy mess much to my chagrin. I don't have any good pictures of the mess but when I cooked the gnudi in water it pretty much disintegrated. I tried making it again a few days later after putting the leftover uncooked gnudi in the freezer and just sautéing it in some butter and not bothering with boiling it in water. It turned out much better this way with the outside being slightly brown while the inside was nice and soft and oh so cheesy.

Here's the ribeye. You can see the really nice marbling throughout.

I wanted to make this in a way to highlight the natural flavor so I used just kosher salt and fresh ground black pepper. I seasoned it about 2 hours before I cooked it after having it sit out for about 2 hours to help temper it.

I cooked this on a gas grill which was at a temperature of about 350F inside. I checked the internal temperature of the steak, turned it twice, and took it off the grill when it hit an internal temperature of 130F. I then let it rest for about 10 minutes before slicing it.

I made some sweet potatoes and Brussels sprouts as sides. The ribeye was sliced against the grain which makes it taste much more tender:

I also made some Béarnaise sauce since I've read that it's the only fitting sauce for a nice steak. I haven't made many sauces and not even Hollandaise so this was a challenge for me. It turned out alright but after I took it off the burner for about 10 minutes (so I could plate and get ready to take pictures) it separated which stressed me out a lot. I was seriously about to just throw the sauce out and just throw my hands in the air in frustration. Then I found this video (the video is for Hollandaise but it applies to Béarnaise since Béarnaise is directly related to the mother sauce of Hollandaise) and managed to rescue the sauce.

Here it is paired with a nice Old Fashioned made with Four Roses Yellow Label. I forgot to buy oranges so there's no orange peel as a garnish. I'm quite happy with the photography of this meal.

The next night I based the meal around Thomas Keller recipes. I started off with something I've been wanting to make for a few years: Ratatouille. Technically it's called Confit Byaldi but the version that a lot of people are familiar with is the version you see in Pixar's Ratatouille. Well, what actually happened is that Brad Bird had Thomas Keller as a consultant for the film and asked him to make a version of the French dish Ratatouille that would look more stunning on screen. Confit byaldi was first documented by Michel Guérard but modified by Thomas Keller in his 1999 cookbook, The French Laundry Cookbook.

I followed this recipe. Here's a picture of me slicing the Asian eggplant with my Chinese cleaver. If I were to make this again I'd probably invest in a mandolin slicer. I'm also planning on getting a good knife soon as the Chinese cleaver isn't as precise as I'd like.

The piperade:

Before going in the oven:

Fresh out of the oven:

Here's my plating of the confit byaldi with the vinagrette. I'm just recently getting into elevating my plating and I think it's an OK attempt but could use a bit more work.

Slightly more "artsy" picture:

I also did a roasted chicken which is one of the things Thomas Keller is known for.

Roasted chicken and confit byaldi:

Friday, April 10, 2015

Samsung 220WM Repair

I've been absent for quite some time due to some major changes going on with my life and career path. I may expound more on that in the future but suffice it to say I think it's a good direction for me.

About a year and a half ago I started noticing some issues with my Samsung 220WM LCD monitor which I purchased Fall of 2007. It served me well but it started having issues turning on sometimes. Then a year ago it stopped turning on at all at which point I went to Best Buy and purchased a LG 23EA63 LED monitor.

I recall reading on reddit at some point about someone repairing an old broken monitor by replacing some blown capacitors. I'm not sure why it's taken this long but a couple of weeks ago I decided to disassemble my broken Samsung monitor to see if I could identify any blown capacitors.

I started off by removing the desk mount which is held in by 4 screws, then proceeded to pry open the plastic bezel. I did this using some metal putty knives (the ones you use to patch up your drywall). At first I was pretty scared of breaking the plastic but you can actually be pretty rough with it. I started off at the bottom corners, worked my way up the sides a bit, then opened up the entire bottom edge before working my way all the way around.

Here's what it looks like after removing the plastic bezels:

Close-up of the front bezel:

And here's what the back looks like with the bezels removed:

This is the ribbon that goes to the back:

The board on the left side (looking from the back)

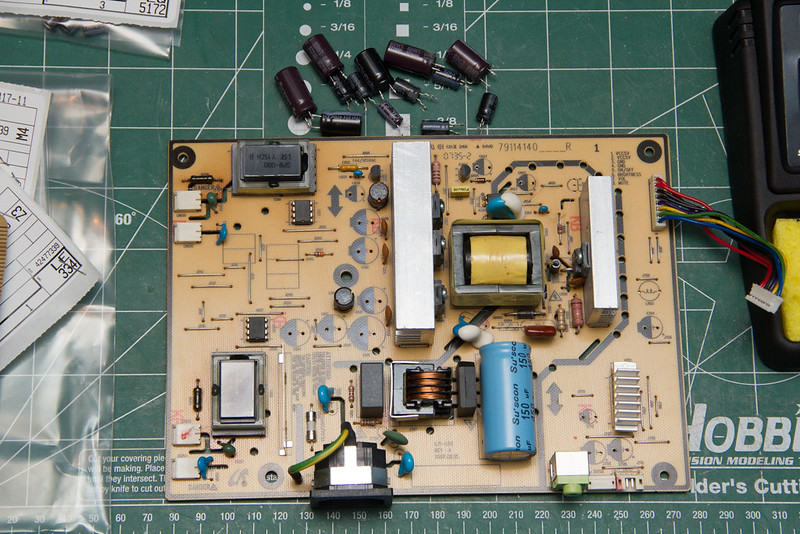

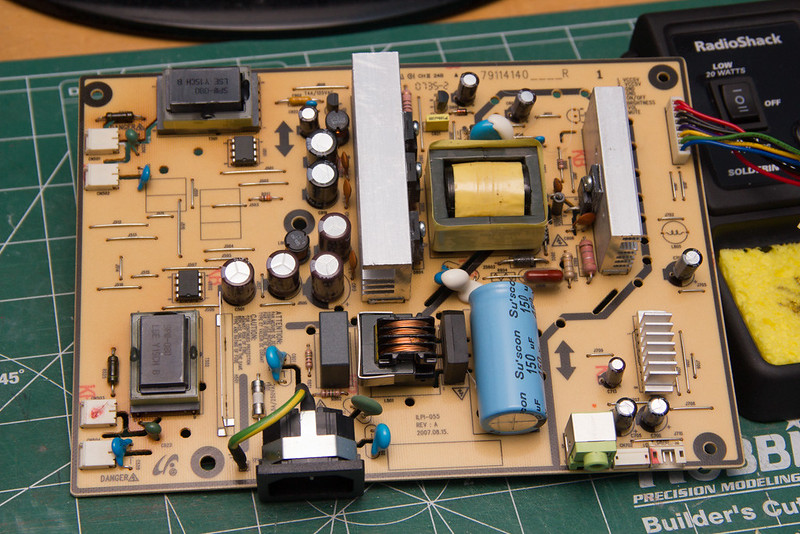

The main board, the one that contains the power supply:

A picture of some of the connector from the speakers for reference:

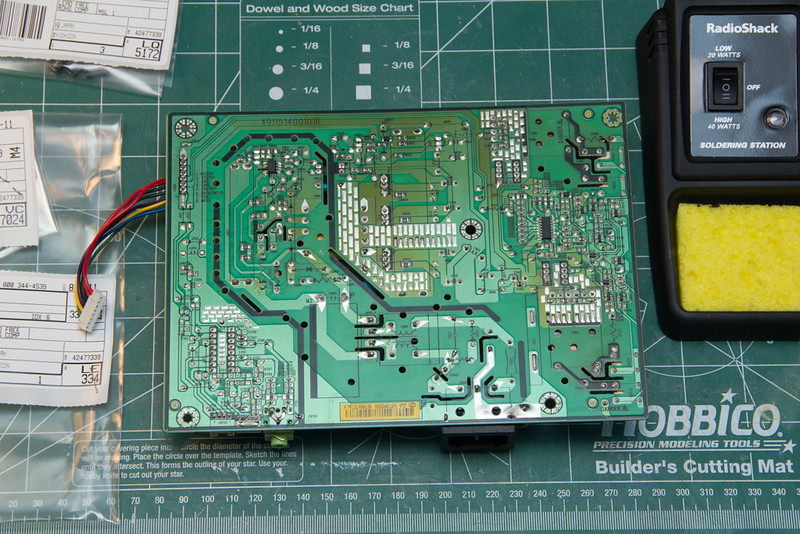

The main board flipped over:

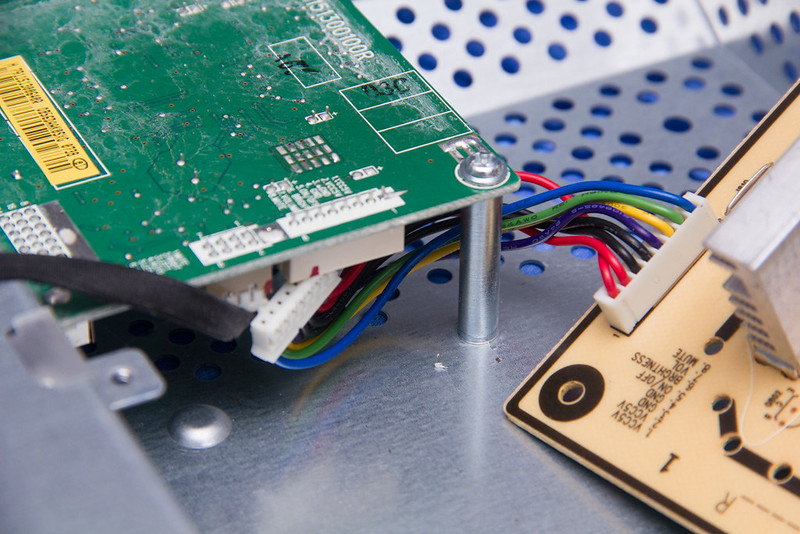

It was tough to remove the connector from the main board so I disconnected it from the other board:

Main board disconnected:

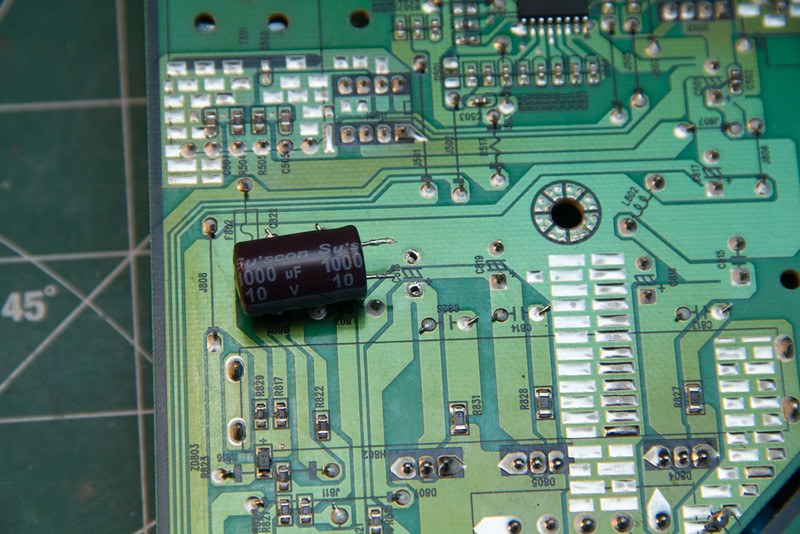

A close-up of the main board. Here you can see some of the blown capacitors which are bulging on the top. A majority of the capacitors are made by Su'scon which is a Taiwanese company. I did some research and found the site Badcaps.net.

They have a list of Bad Caps and also Good Caps

I used the list of Good Caps as a guide when searching for new caps on DigiKey

Here's the new capacitors I ordered. I opted to replace a total of 13 capacitors even though only 3 were bulging. I figured for less than $10 I could replace all of them and not have to worry about some other capacitors failing in a few months.

Here's a list of the ones I ordered:

(2) 1000uF 10V Rubycon

(2) 680uF 25V United Chemi-con

(2) 470uF 25V United Chemi-con

(3) 47uF 25V Nichicon

(3) 220uF 16V Rubycon

(1) 10uF 16V Nichicon

First capacitor removed:

All 13 capacitors removed:

Some of the capacitors

The capacitors soldered. I left all the leads in until I was done so I could snip them together. The last time I soldered anything was when I was in elementary school when my grandpa on my mom's side taught me. It took a couple tries to solder the first capacitor but I got the hang of it pretty quickly. It's so satisfying when you get a nice solder and it just wicks nicely.

The front side of the board with everything soldered. The board is tilted up because of the leads still in the back.

With the leads trimmed the board now sites flat.

All the parts ready to be re-assembled.

Halfway through re-assembly. At this point I hooked it up to my computer to test if it worked. It was a huge relief when it powered on and showed my desktop! I wanted to make sure it worked before snapping the bezel back together since that was honestly the hardest part of the disassembly.

Apparently Foxconn was involved in the making of this monitor:

Double monitor setup!

About a year and a half ago I started noticing some issues with my Samsung 220WM LCD monitor which I purchased Fall of 2007. It served me well but it started having issues turning on sometimes. Then a year ago it stopped turning on at all at which point I went to Best Buy and purchased a LG 23EA63 LED monitor.

I recall reading on reddit at some point about someone repairing an old broken monitor by replacing some blown capacitors. I'm not sure why it's taken this long but a couple of weeks ago I decided to disassemble my broken Samsung monitor to see if I could identify any blown capacitors.

I started off by removing the desk mount which is held in by 4 screws, then proceeded to pry open the plastic bezel. I did this using some metal putty knives (the ones you use to patch up your drywall). At first I was pretty scared of breaking the plastic but you can actually be pretty rough with it. I started off at the bottom corners, worked my way up the sides a bit, then opened up the entire bottom edge before working my way all the way around.

Here's what it looks like after removing the plastic bezels:

Close-up of the front bezel:

And here's what the back looks like with the bezels removed:

This is the ribbon that goes to the back:

The board on the left side (looking from the back)

The main board, the one that contains the power supply:

A picture of some of the connector from the speakers for reference:

The main board flipped over:

It was tough to remove the connector from the main board so I disconnected it from the other board:

Main board disconnected:

A close-up of the main board. Here you can see some of the blown capacitors which are bulging on the top. A majority of the capacitors are made by Su'scon which is a Taiwanese company. I did some research and found the site Badcaps.net.

They have a list of Bad Caps and also Good Caps

I used the list of Good Caps as a guide when searching for new caps on DigiKey

Here's the new capacitors I ordered. I opted to replace a total of 13 capacitors even though only 3 were bulging. I figured for less than $10 I could replace all of them and not have to worry about some other capacitors failing in a few months.

Here's a list of the ones I ordered:

(2) 1000uF 10V Rubycon

(2) 680uF 25V United Chemi-con

(2) 470uF 25V United Chemi-con

(3) 47uF 25V Nichicon

(3) 220uF 16V Rubycon

(1) 10uF 16V Nichicon

First capacitor removed:

All 13 capacitors removed:

Some of the capacitors

The capacitors soldered. I left all the leads in until I was done so I could snip them together. The last time I soldered anything was when I was in elementary school when my grandpa on my mom's side taught me. It took a couple tries to solder the first capacitor but I got the hang of it pretty quickly. It's so satisfying when you get a nice solder and it just wicks nicely.

The front side of the board with everything soldered. The board is tilted up because of the leads still in the back.

With the leads trimmed the board now sites flat.

All the parts ready to be re-assembled.

Halfway through re-assembly. At this point I hooked it up to my computer to test if it worked. It was a huge relief when it powered on and showed my desktop! I wanted to make sure it worked before snapping the bezel back together since that was honestly the hardest part of the disassembly.

Apparently Foxconn was involved in the making of this monitor:

Double monitor setup!

Subscribe to:

Comments (Atom)